Home construction projects tend to focus on tile, stone, and marble setup. Throughout the years it has become a growing number of popular ways to redo the cooking area or restrooms to feel more contemporary. Stone, tile, and marble provide your home with more resale value and much more beauty. Unfortunately for DIY people out there, these are difficult products to work with due to their thick and brittle nature.

Stone, tile, and marble cutting all need advanced stone cutting tools to guarantee tidy lines. Anyone who wishes to deal with any of these products must purchase the proper stone cutting tools and learn how to use them. Normally specialists are needed when laying marble, tile or stone. The fabrication process itself can be quite complicated, time-consuming, and pricey if errors are made.

All professional producers have specialized stone cutting tools that they use on the job. Saws are probably the most essential stone cutting tool required for any DIY job. Different materials need different methods of cutting; dry or wet. And going here to this article to read on the many uses of this article by going here.

Quarry Choose

A pick is a tool utilized primarily during quarrying. [10] With a wood manager, approximately 70-80 cm long the quarry choice has a metalhead with points on one or both ends. [11] The points themselves act successfully like a point sculpt but the long handle allows the user to impart much more force, though less control, with each stroke. On quarry faces the marks of the quarry pick are recognizable as long, often curved lines where the quarrymen struck the same spot consistently prior to moving along the rockface.

Characteristic marks of the Roman quarry choice can be seen on extant quarry deals with and particularly in the channels excavated around blocks during quarrying. Very clear examples have been documented by Rockwell at Aphrodisias and in the Backdale quarry at Iscehisar (ancient Dokimeion). [12]

Carver’s Choose

The carver’s or carver’s choice is a miniature variation of the quarry pick, with a manage no greater than 60 cm long and frequently more like 30-40 cm. [19] The metal head of this small choice is usually pointed at either both ends or simply one.

The tool is accepted two hands and its head strikes the stone vertically, leaving marks comparable to the point to sculpt when used in this manner. Just how much this tool was utilized in the Roman period is unknown but it was widely used on marble and granite in Middle ages Italy, as on Orvieto cathedral, where it was used in place of the tooth chisel for rough shaping.

Angle Mills

Angle mills are likewise called a side or disc mills. They are a handheld power tool utilized for cutting, grinding and polishing.

Angle mills can be powered by an electric motor, fuel engine or compressed air. The angle grinder motor drives a tailored head at a right-angle on which is installed an abrasive disc or a thinner cut-off disc, either of which can be replaced when used. Angle grinders usually have an adjustable guard and a side-handle for two-handed operation.

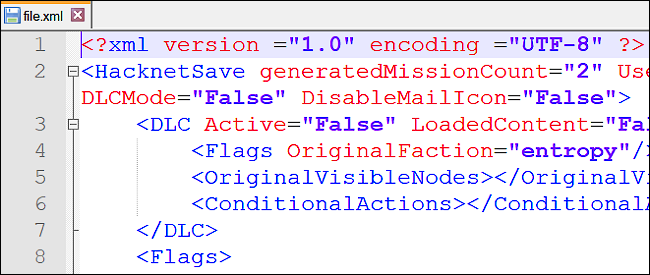

Tile Saws

You can use a regular circular saw, geared up with a diamond blade, to wet-cut your marble. Because this will be an untidy task and you’ll require your garden hose, you’ll wish to work outdoors.

Protect your marble piece by putting it on a 2-in. A thick piece of rigid foam. Mark your cutting line with a marker on a large piece of tape.

Marble Blades

Marble is a tough crystalline type of limestone used primarily in sculpture and architecture, marble is a softer natural stone and needs a harder bond to cut. Marble diamond blades are produced using 2 methods.

Vacuum Brazing manufactured by welding synthetic diamond particles onto the outside edge of the circular steel blade in a vacuum brazing heater. All of the diamond particles are on the exterior edge of the blade, with no metal diamond mix, vacuum brazed blades will cut a variety of material consisting of, concrete, masonry, steel and various irons.

Electroplating

blades utilizing diamonds embedded in metal coating, generally of nickel electroplating onto a steel blade base, can be made to be really thin as much as 10 micrometres thick, for accurate cutting

Diamond blades used to cut marble sometimes have a diamond that can be visible on the edge of the blade but in many cases in bigger sizes utilize the sintering method for bridge saw blades.